Vacuum technology, though often overlooked, is a cornerstone of modern industrial and scientific endeavors. From manufacturing processes to space exploration, the manipulation of vacuum plays a crucial role in various applications. In this article, we’ll delve into the intricacies of vacuum technology, exploring its history, principles, applications, challenges, and future prospects.

History of Vacuum Technology

The roots of vacuum technology can be traced back to the 17th century when Evangelista Torricelli invented the mercury barometer, demonstrating the existence of atmospheric pressure. Later, in the 19th century, the development of vacuum pumps by scientists like Robert Boyle and Guillaume Amontons paved the way for more sophisticated experiments and applications.

Principles of Vacuum Technologies

Pressure and Vacuum

Vacuum is essentially a space devoid of matter, where the pressure is significantly lower than atmospheric pressure. Understanding pressure and its effects on materials is fundamental to vacuum technologies.

Gas Laws

The behavior of gases under different pressure conditions is governed by various gas laws, such as Boyle’s Law and Charles’s Law. These laws are essential for designing vacuum systems and predicting their performance.

Types of Vacuum Pumps

Vacuum pumps are devices used to create and maintain a vacuum in a closed system. There are several types of vacuum pumps, each suited for specific applications:

Positive Displacement Pumps

These pumps work by trapping and transporting gas molecules from the system. Examples include rotary vane pumps and piston pumps, known for their high efficiency and robustness.

Momentum Transfer Pumps

Momentum transfer pumps, such as turbomolecular pumps and diffusion pumps, rely on the transfer of momentum between gas molecules and solid surfaces to create a vacuum.

Entrapment Pumps

Entrapment pumps capture gas molecules by adsorption or chemical reaction on solid surfaces or within porous materials.

Applications of Vacuum Technology

Vacuum technologies finds applications across various industries and scientific fields:

Semiconductor Manufacturing

In semiconductor fabrication, vacuum systems are integral to processes like chemical vapor deposition and physical vapor deposition, essential for depositing thin films of materials onto silicon wafers with high precision.

Scientific Research

In scientific research, vacuum chambers are used to create controlled environments for conducting experiments in fields like material science, physics, and chemistry. High-vacuum conditions are crucial for studying the behavior of materials and particles under extreme conditions.

Vacuum Technology in Space Exploration

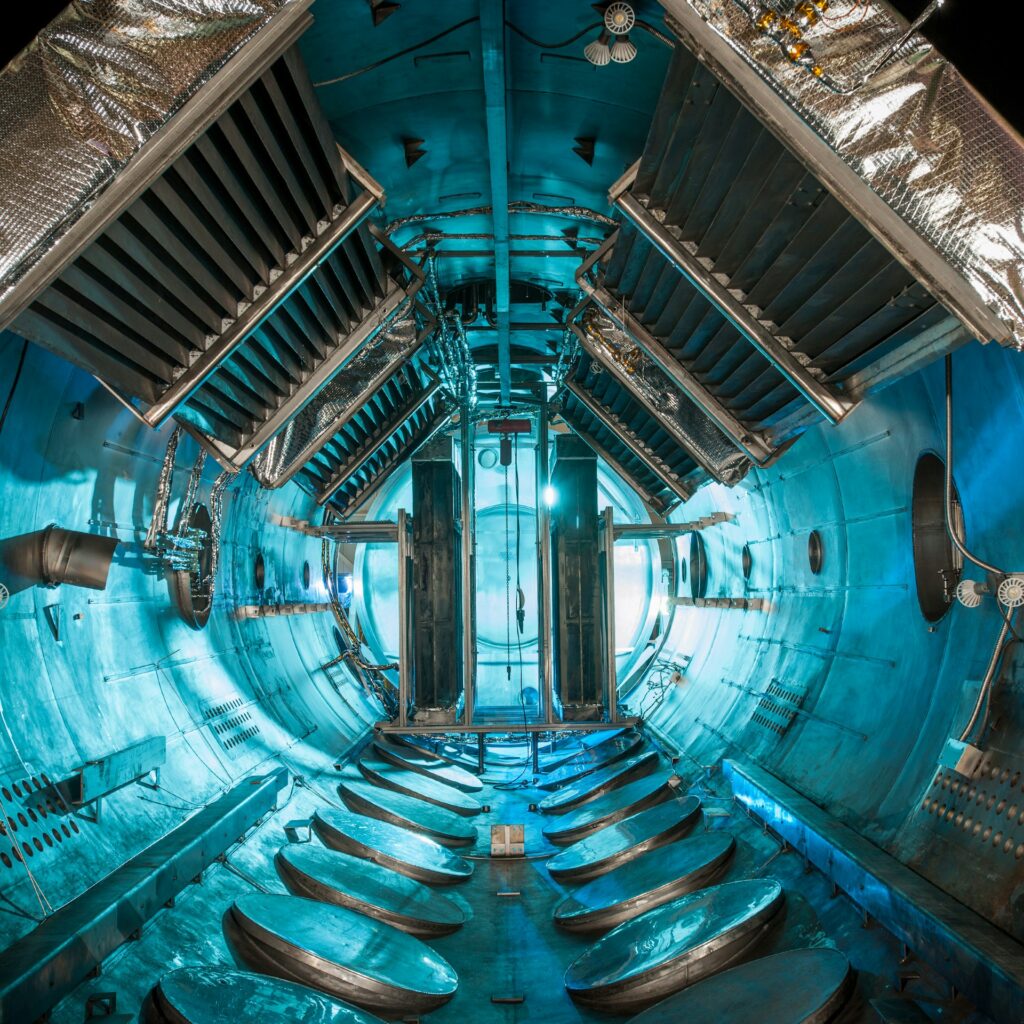

The harsh environment of space requires advanced vacuum technology for spacecraft propulsion, life support systems, and scientific instruments. Vacuum chambers simulate space conditions for testing spacecraft components and ensuring their reliability.

Challenges and Limitations

Despite its widespread use, vacuum technology presents challenges such as maintaining ultra-high vacuum conditions, preventing leaks, and handling corrosive or reactive gases. The development of novel materials and sealing techniques is essential for overcoming these limitations.

Future Trends in Vacuum Technology

Advancements in materials science, nanotechnology, and quantum computing are driving innovations in vacuum technology.

Conclusion

Vacuum technology has revolutionized industries and scientific research, enabling breakthroughs in manufacturing, electronics, and space exploration. By understanding the principles of vacuum and harnessing its power, we continue to push the boundaries of what’s possible.